What are the challenges with reusable containers?

Whether special load carriers, mesh roll containers, small load carriers or pallets. These days, their use presents companies with costly challenges.

- Shrinkage, loss, damage

- Inefficient use

- No transparency about the stock

The BOX ID solution approach

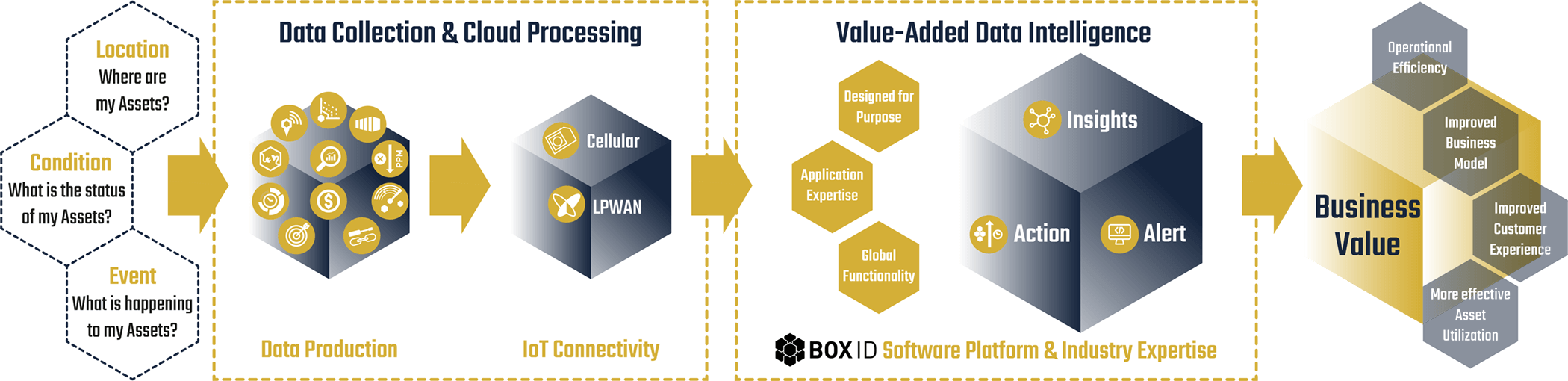

The BOX ID system solves these challenges by providing state-of-the-art container management software with analytics. By using the latest IoT and identification technologies, we create the necessary visibility and automation for companies exactly where it is needed.

We generate real-time information about the availability and location of your assets and their condition (condition monitoring) right from the start of the system:

- Higher availability and optimized turnaround times

- Up to 20% reduction in container requirements

- Elimination of costs for bottleneck supply and replacement packaging

- Significant reduction in shrinkage of the container fleet

With BOX ID, you can reduce the loss of containers and other mobile assets to near zero, on average by around 95%.

With BOX ID, you can significantly reduce lead times for returnable packaging, on average by around 20%.

With BOX ID, you need significantly fewer mobile assets for the same availability, on average around 15%.

BOX ID System for your returnable packaging management

We merge data directly from your physical assets with various third-party systems (ERP, PPS, MES, etc.) and manual ad-hoc information (WE, QM) to give you a complete view with this digital twin.

With this approach, you can manage a large number of assets in real time with minimal resources, optimize processes and even make the data available to other systems. A wide range of applications and specific functions generate measurable benefits for you in the shortest possible time.

Additional applications and special functions

We have learned that one size does not fit all. To provide a valuable solution for businesses, we focus on industry-specific add-ons and special features that add immediate value. These include

- Turnaround time analyses across all supplier locations, automated reports

- Location database for resolving the internal container flow in the plant

- Processing of all EPCIS events, optional connection to SAP EWM

- Tags with multiple functions - e.g. active localization + RFID

- RTP Maintenance/Overhaul (new development)

Matthias Piekarczyk

Head of Sales

Talk to us!

Do you have a specific question or would you like to learn more about us or our product? Whatever you need to know, whether it is about various features or information security, we will be happy to answer your questions in a joint discussion.

Implementation with the help of our partners

We work with integration partners, software system houses and ERP OEMs. This enables us to offer you significant added value even with complex integrations of our solution into your data landscape or with specific customizations. Please do not hesitate to contact us.

Our growing network of partners and integrators, together with our strategic value-added resellers, enables us to easily provide global support. If you are interested in becoming an official reseller or integration partner, please contact us for a personal meeting.

System integration

Radio network

Connected load carriers

FAQ on container management and returnable container management

Looking for a versatile and innovative solution for efficient storage and secure transportation of goods? Then returnable containers combined with the BOX ID system for efficient container management is the solution for you. Here are some of the most frequently asked questions about our tracking solution and returnable containers.

What are returnable containers?

Returnable containers are load carriers and transport solutions that have been developed for the transportation and storage of goods. Whether small load carriers, large load carriers, roll containers or pallets, a returnable container moves back and forth between you and your customer. They transport, store and organize your flow of goods in the most time-saving way possible.

What is the BOX ID System?

The BOX ID system is an innovative software solution for tracking and managing shuttle containers. It enables complete visibility of goods tracking, safe transportation and optimization of your carrier fleet.

How does the BOX ID System work in conjunction with pendulum containers?

The BOX ID System enables the accurate tracking and monitoring of returnable containers in “real time”. It provides detailed information on the location, contents and condition of the containers, enabling optimized use, management and safe transport. By aggregating the data of all containers in circulation, the system maps the complete inventory of the returnable containers in real time and offers the user resource-saving management and optimization options in operation via a wide range of analysis functions and automation.

What advantages does the BOX ID system offer companies?

The BOX ID system in combination with returnable containers offers companies the following benefits:

- Efficient returnable container management and optimized transport of goods.

- Real-time tracking of containers for precise inventory control.

- Minimization of losses through container tracking.

- Increased efficiency: By using returnable containers, you can optimize your packaging in the supply chain, you can transport more goods from A to B or reduce the returnable container fleet while maintaining the same output. Whether small or large load containers, roll cage boxes or pallets, your goods can be sorted and transported efficiently to the customer.

- Cost savings: With our tracking solutions, you not only minimize losses in your logistics and container management, but you also manage your reusable container pool more efficiently and with fewer resources thanks to the system’s automation. You save money.

- Environmentally friendly: Returnable containers can be reused at any time and reduce disposable packaging. They can safely deliver many more goods on one transport route and thus contribute to reducing environmental pollution. Returnable containers are durable means of transportation which, combined with container management software and tracking, will provide your company with efficient storage and safe transportation for years to come.

How does the BOX ID System support returnable container management?

The BOX ID System facilitates returnable container management by recording, allocating and tracking containers. It ensures efficient use, high availability and minimal losses of transport and storage containers.

What functions does the BOX ID System offer in addition to tracking returnable containers?

In addition to tracking returnable containers, the BOX ID System offers other functions such as inventory, stock management, rental models, minimization of losses and improved customer service through precise information on the status of deliveries and the location of goods.

What is returnable container management?

Returnable container management involves the organization, monitoring, and control of containers throughout the logistics process. It includes the recording, allocation, tracking and maintenance of containers to ensure the most efficient use, continuous availability and minimal container loss.

What does it mean to track (returnable) containers?

Effective tracking of returnable containers plays a central role in optimizing supply chain processes. The ability to track containers in real time allows you to monitor the location, contents, and often the condition of containers. This enables more accurate planning, more efficient use of your resources, faster response to changes or orders, and minimization of losses of transport and storage containers.

What are the advantages of returnable container management and tracking?

- Inventory control and optimization: Container tracking allows companies to keep track of their small load carriers, large load carriers and transport containers in general. This allows stocks to be optimized and reorders to be triggered if necessary.

- More efficient transport tracking and optimization: Real-time tracking of returnable containers enables companies to see the locations and thus optimize transport routes and transport times. The entire supply chain benefits from the information and associated optimizations.

- Minimized losses: By tracking the returnable containers, potential losses or theft of containers are identified. With the appropriate countermeasures, losses can be minimized and the safety of containers and goods ensured.

- Optimized customer service: By tracking your containers in detail, you can provide accurate information about the status of the delivery and the location of the goods for internal company processes and for your customers.